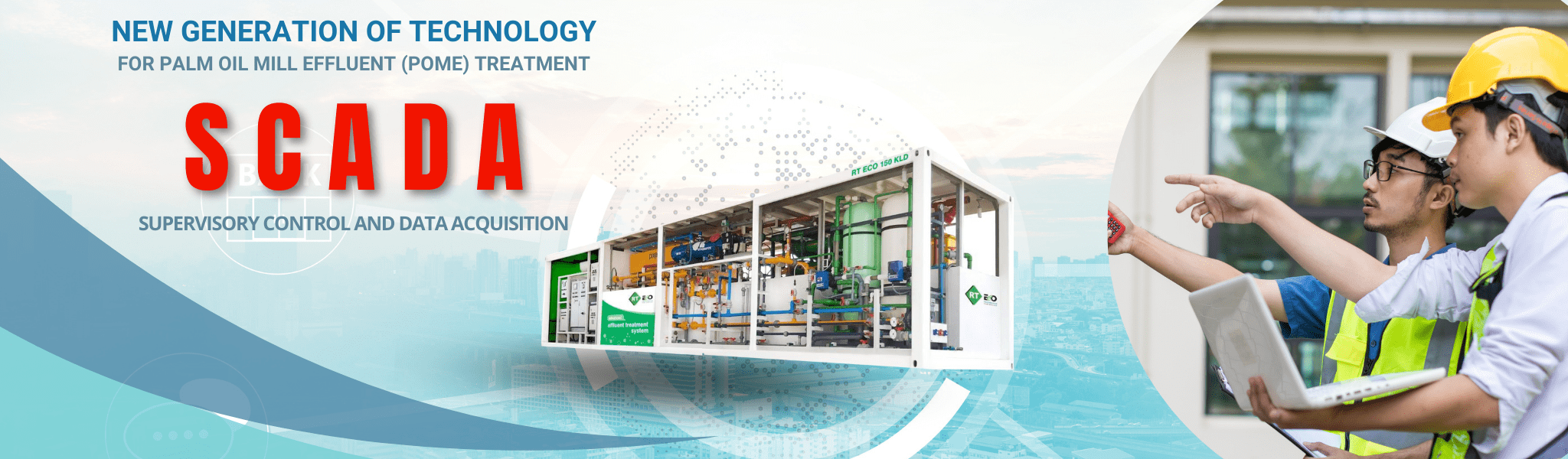

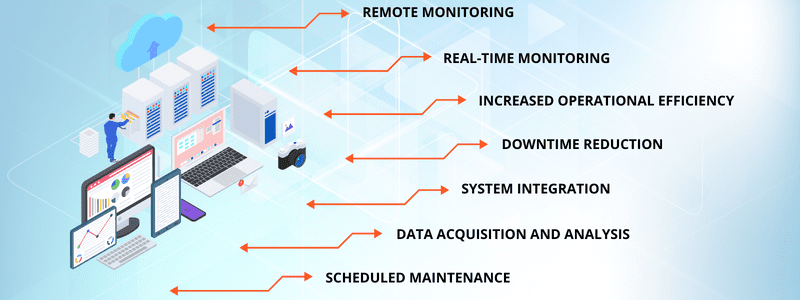

RT ECO™ - Technology Using SCADA (RealTime) Monitoring System

By utilizing SCADA in palm oil effluent treatment, it is expected that the Mill will be able to automate and monitor effluent treatment processes more effectively. One of which allows operators to monitor and control various important parameters in real-time, such as temperature, pressure, pH, and noise levels, which affect the quality and efficiency of effluent treatment.

Here are the main benefits of SCADA in Palm Oil Effluent Treatment:

-

Process Automation: By leveraging SCADA, mill can automate most of the effluent treatment processes. This reduces reliance on manual intervention, improves operational efficiency, and reduces the risk of human errors.

-

Real-Time Monitoring: SCADA enables real-time process monitoring remotely. Operators can access up-to-date information about the operational conditions of the mill from anywhere, even from their mobile devices, enabling quick responses to condition changes

-

Quick Problem Identification: With real-time monitoring capabilities, SCADA allows early detection of disturbances or anomalies in the effluent treatment process. This enables the operational team to identify problems quickly and take corrective action before they escalate.

-

Performance Improvement: With the ability to monitor operational parameters in real-time, SCADA helps optimize mill performance. This includes reducing machine downtime, improving energy efficiency, and reducing effluent generation.

-

Operational Safety: SCADA also plays a role in improving operational safety at the mill. By real-time monitoring critical parameters such as pressure and temperature, SCADA can detect potential hazards or equipment failures early, allowing appropriate preventive actions to be taken.

With the ability to automate processes, monitor conditions in real-time, and identify problems quickly, SCADA is expected to help mill optimize their operations and reduce overall environmental impact. Additionally, the long-term benefits offered by this RT ECO™ technology make it a promising investment for the future of the palm oil industry.