PALM OIL MILL EFFLUENT (POME)

Extracting palm oil from fresh fruit bunches (FFBs) generates liquid waste called palm oil mill effluent (POME). In the old extraction process, three significant operations create the bulk of POME:

- Sterilizing fresh fruit bunches

- Clarifying extracted crude palm oil: pressing station, separation, clarification

- EFB pressing

The mill discharges about 0.6-meter cube of POME for every ton of fresh fruit bunches processed. Fresh POME is hot (temperature 60-80°C), acidic (pH of 3.3-4.6), thick, brownish liquid with high solids, oil and grease, COD, and Biological Oxygen Demand (BOD) values.

Challenges in Handling

Here are some key challenges faced by palm oil mills in managing their effluent:

- Routine Drainage: Palm oil mill effluent needs to be drained regularly to prevent buildup that can disturb the environmental balance. This drainage process requires significant time and resources.

- Risk of Embankment Landslides: Palm oil mills often face the risk of embankment landslides caused by excessive effluent or inadequate construction techniques. This can result in water pollution and damage to natural habitats.

- Leakage from Effluent Ponds: The moisture and acidity of palm oil mill effluent can cause cracks or leaks in storage ponds. This can lead to soil and groundwater contamination in the surrounding areas.

- High BOD Levels: Palm oil mill effluent often has high Biochemical Oxygen Demand (BOD) levels, indicating high organic content. If not properly treated, this can lead to decreased oxygen levels in the water, endangering aquatic life.

- Pond Overflow: When the capacity of effluent storage ponds exceeds its limits, overflow can occur, causing effluent to spread into the surrounding environment and contaminating groundwater and rivers.

- River Fish Mortality: Increased levels of palm oil mill effluent in rivers can lead to mass fish deaths and other species. This not only harms the environment but also disrupts the livelihoods of communities dependent on these natural resources.

Regulation of the Minister of Environment of the Republic of Indonesia Number 5 of 2014 concerning Waste Water Quality Standards

WASTEWATER QUALITY STANDARDS FOR PALM OIL INDUSTRY BUSINESSES AND/OR ACTIVITIES

| PARAMETER | Highest Concentration (mg/L) | High Pollution Load (Kg/Ton) |

|---|---|---|

| BOD5 | 100 | 0.25 |

| COD | 350 | 0.88 |

| TSS | 250 | 0.63 |

| Oil and Grease | 25 | 0.063 |

| Total Nitrogen (as N) | 50 | 0.125 |

| pH | 6.0 - 9.0 | |

| Highest waste discharge | 2.5 m2 per ton of palm oil products (CPO) | |

Notes:

- The highest levels for each parameter in the table above are expressed in milligrams of the parameter per liter of waste water

- The highest pollution load for each parameter in the table below is expressed in Kg parameters per ton of palm oil products (CPO)

- Total Nitrogen = Organic Nitrogen + Total Ammonia + NO3 + NO2

Current Views of Biological Treatment Method

Evolution in POME Treatment

-

Aqua Jaya Sumber Advanced Hybrid Electro-Chemical technology is a combination of Electro-Coagulation & Electro-Oxidation process (RT ECO™)

-

RT ECO™ is a new generation of technology for Palm Oil Mill Effluent (POME) treatment and creates sustainability in palm oil industry

-

It is an affordable technology to treat Palm Oil Mill Effluent (POME) which have a lot of oil & grease, suspended solid, organic and in-organic contaminants

ELECTRO-COAGULATION

Process where flocculating metal ions are electrolytically added to polluted water at an anode, and gas microbubbles are realeased at a cathode.

The reactive and excited state causes contaminants to be released from the water and destroyed or made less soluble.

ELECTRO-OXIDATION

Electron transfer to or from a molecule or ion changing its oxidation state (H+ , OH-ion , H2O and electrons)

Process oxidizes dissolved organic and ammonia compounds, sulfides, etc, to carbon dioxide, water, nitrogen, and simple salts.

Aqua Jaya Sumber is The Solution to POME Treatment

100% Indonesian company and innovation that meets the discharge Standards of Kementrian Lingkungan Hidup dan Kehutanan (KLHK).

The system as a Service (SaaS) model - is affordable, efficient & effective.

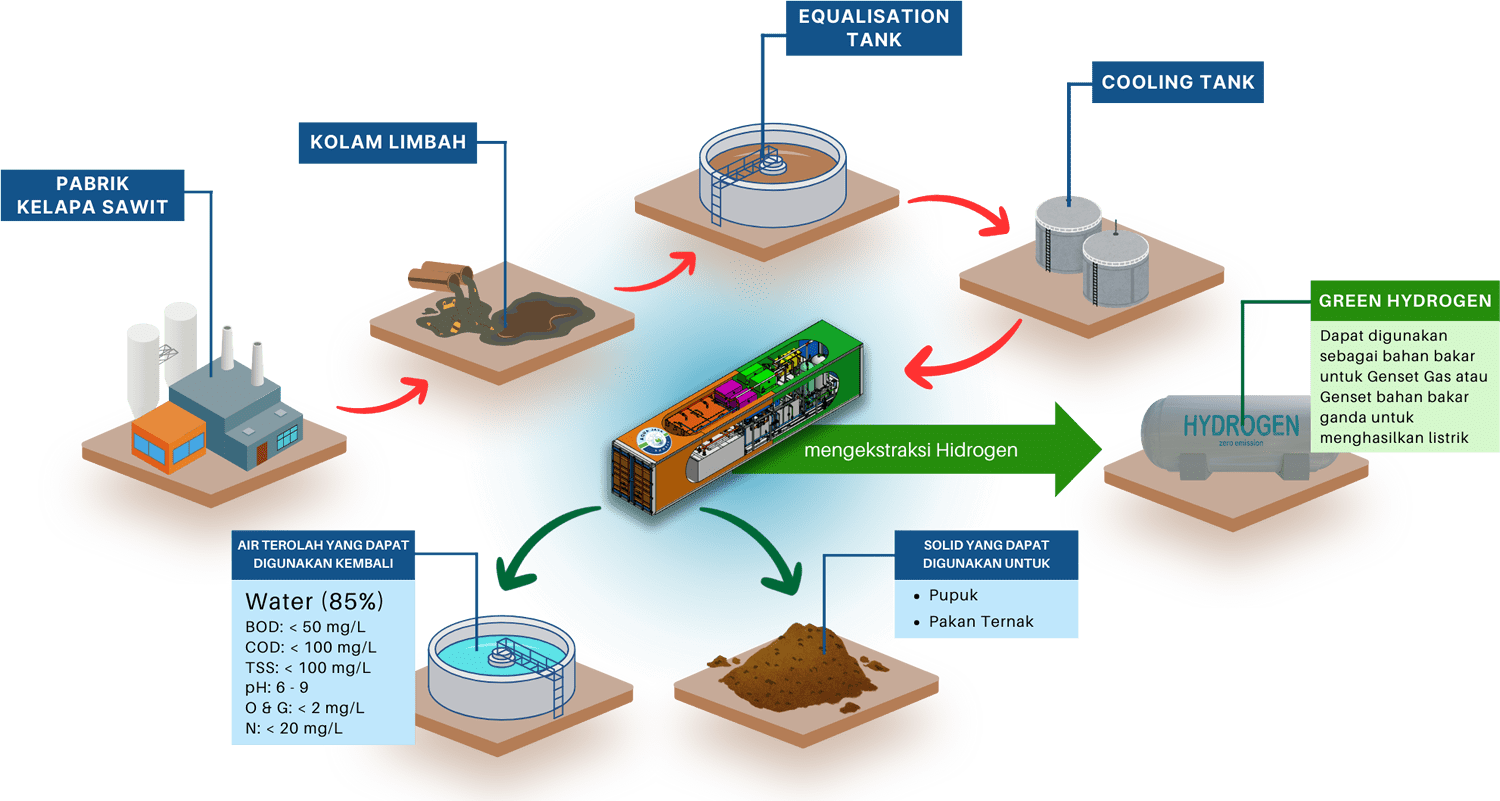

Reused treated water, organic sludge to fertilizer, and green hydrogen as clean energy.

Technology Efficiency Which Removes

RT - ECO Advanced Hybrid Electro-Chemical Treatment System has complied with the requirement and recomendation of KLHK which can treat RAW & ANAEROBIC POME.

The system can remove Organics, Suspended Solids, Turbidity, Odour, Colour, Fats, Oil & Grease, and Heavy Metals.

Please inquire for more information and consultation at info@aquajaya.co.id